The modern infrastructure heavily relies on electricity whereas transformers and power ratings are also significant elements in the energy generation, transmission, and distribution systems. The branch of MVA (Mega Volt Amperes) is one of the most common terms that electrical engineering practitioners encounter. It is one of the important quantities of a system’s apparent power. But what is MVA, and how does it relate to transformers? More importantly, why is it instrumental in the evaluation of power systems as far as efficiency and capacity are concerned?

Classes on MVA and its application in electric systems will be made easier to grasp by answering a series of guiding questions along with outlining some fundamental principles that you need to know. It will start from the basics of power ratings and move on to the importance of MVA in the design of transformers, its relation to real and reactive power, and the performance of electrical systems. If your profession is in the energy industry, or if you are just trying to familiarize yourself with electrical engineering terms, then this detailed FAQ will get you through to MVA’s practical application and relevance in electrical infrastructure.

What is MVA and How is it Used in Electrical Systems?

MVA stands for Megavolt-Amperes, a unit of a transformer’s or generator’s capacity to electrical load. In general, MVA or apparent power describes the total power in a system, combining both real power, expressed in MW, and reactive power, expressed in MVAR. MVA is the most important unit that defines the specs of a transformer and generator. It is needed in operational environments to design and maintain electrical systems, especially in power generation, transmission, and distribution to make sure there is reasonable structure and functionality of the network.

Understanding MVA and its Role in Power Systems

Megavolt-Amperes MVA, describes the apparent power within a power system, which includes both active power (MW) and reactive power (MVAR). This parameter is central to power systems design, operations, and optimization. Provided power differs from the utilized or active power as it also includes power which is stored in reactive components like inductors or capacitors, and then returned to the source. This means that the power stored is equal to supplied energy minus utilized energy.

MVA also serves as a fundamental unit in transformer and generator bills. It dictates the maximum permissible electrical load that can be used without resulting in overheating and efficiency loss. This serves as a guide in equipment loading and interconnecting service zones and distribution substations on the transmission and distribution systems. In addition, MVA serves as a rating unit for planners of the grid whose focus is on system stability, voltage fluctuations, and power factor correction.

The Difference Between MVA, MW, and KVA

Understanding the differences between MVA, MW, and KVA is critical in power engineering as these units define distinct characteristics of electrical systems.

- MVA (Mega Volt-Amperes): MVA represents the apparent power in an electrical system, combining both active (real) power and reactive power. Apparent power quantifies the total power capacity of equipment or systems, including losses caused by reactance. It is calculated using the formula MVA = (Voltage × Current) / 1,000,000 and is independent of the power factor.

- MW (Mega Watts): MW measures the active (real) power in a system, effectively describing the usable power for performing work, such as running machines or lighting. Real power is a subset of apparent power and is influenced by the system’s power factor. It is calculated with the formula MW = MVA × Power Factor.

- KVA (Kilo Volt-Amperes): KVA is a smaller-scale version of MVA, representing 1,000 Volt-Amperes. It is used in applications of lower capacity, such as for smaller transformers or generators. Like MVA, it also measures apparent power and does not account for the system’s power factor.

Simply put, MVA is the total power, MW is the usable power, and KVA is apparent power on a smaller scale. The relationship between these units hinges on the system’s power factor, which describes the efficiency of converting apparent power into real power. Understanding these distinctions is essential when designing, selecting, or operating electrical equipment to ensure optimal performance and compatibility.

Why is MVA Important in Power Plants?

The values of MVA (Mega Volt Amperes) are crucial in a power plant setting because they show the entire amount of materials power generated by the Set, Transformer, and other electric staff and machinery. Computed MVA helps in determining whether the system can adequately handle both the active (MW) and the reactive components, facilitates maintenance of voltage stability, and allows for efficient energy transmission. Power plants usually develop their MVA rating to indicate the unlimited amount of work that can be supplied without endangering the performance of the electric plant. However, the MVA lower value indicates that the electric plant is underutilized. In addition to that, an MVA properly evaluated has to be set and assists in procuring wires of other electrical facilities to be offered to amplifying schemes with minimum risk for overloads or power systems in their inadequacy. This makes it a highly significant consideration for proactive over power systems and equipment to systems in multi-power networks.

How are MVA Transformers Rated and What Does it Mean?

MVA (Mega Volt-Ampere) ratings are equivalent to how much energy a transformer can use in a single operation, in reactive and active power combined. This rating is identified by measuring the voltage and current of the transformer, and then adjusting it for practicable energy and heat constraints. The MVA rating guarantees that the transformer will perform without overheating and avoid voltage reductions during heavy load conditions. Additionally, the rating assists in system transformer matching concerning the load and the potential increase of it later on.

Decoding the Nameplate on a Transformer

The nameplate of a transformer contains crucial data necessary for its proper selection, installation, and operation. Typically, the nameplate includes the following information:

- Rated Power (MVA or kVA): Indicates the maximum apparent power the transformer can handle under normal conditions, considering efficiency and thermal constraints.

- Voltage Ratings: Specifies the primary and secondary voltages for which the transformer is designed. These values are crucial for ensuring compatibility with the system’s voltage levels.

- Frequency: Displays the operating frequency, most commonly 50 Hz or 60 Hz, depending on the regional power grid standards.

- Impedance: Usually expressed as a percentage, this value identifies the voltage drop across the transformer under full load and aids in fault current calculations.

- Cooling Class: Denotes the cooling method used, such as ONAN, ONAF, or OFAF, which impacts the operational efficiency and thermal performance.

- Winding Connections: Includes details about the vector group, which describes the phase displacement and connection type (e.g., Delta or Wye).

- Short-Circuit Withstand Capability: Indicates the transformer’s ability to withstand specified fault currents for a short period without sustaining damage.

- Manufacturer and Serial Number: Provides traceability and technical support information.

Understanding these details helps ensure the transformer aligns with system requirements, optimizes performance, and enhances operational safety. Proper interpretation of the nameplate also aids in troubleshooting, maintenance, and planning for future system expansions.

How to Calculate the MVA Rating of a Power Transformer

To calculate the MVA rating of a power transformer, I first need to know the transformer’s rated voltage (kV) and rated current (A) for each winding. The formula for determining the MVA rating is straightforward:

MVA = (kV × A × √3) / 1000 (for three-phase transformers)

MVA = (kV × A) / 1000 (for single-phase transformers)

I’ll start by taking the voltage rating between the line terminals (line-to-line voltage for three-phase systems) and multiply it by the rated current. For three-phase transformers, I account for the √3 factors, as it reflects the relationship between line and phase values in balanced systems. The result is then divided by 1,000 to convert the value from kVA to MVA. This method provides the operational capacity of the transformer and ensures accurate planning for load demands and system integration.

Understanding the Power Rating and Voltage Specifications

For a transformer to function without overheating, its power rating is usually defined in MVA and must not exceed its maximum ability to transfer electrical energy. These ratings are determined by the expected load and operational conditions of the transformer. A rating ensures that the expected power demand can be met with the needed resources, and takes efficiency, temperature rise, and cooling systems into account. As such, selecting the correct power is necessary to eradicate the possibility of equipment malfunction.

Together with the power rating, voltage specifications are equally meritorious because they delineate the primary and secondary input and output levels the transformer can operate at. In addition, the voltage has to be in alignment with the system requirements. In conjunction with this information, the transformer’s ability to adjust the secondary output voltage level concerning the changes in load on the primary side also acts as a gatekeeper to ensure proper operational functionality of the device. Hence knowledge of power rating and voltage specifications is critical when trying to select the right transformer and incorporating it into the electrical power system.

What are the Specifications of a 100 MVA Transformer?

A 100 MVA transformer is a high-capacity electrical device designed to handle a maximum apparent power of 100 megavolt-amperes (MVA). Key specifications include:

- Primary Voltage: Typically rated for high voltage levels, such as 132 kV or 220 kV, depending on the system requirements.

- Secondary Voltage: Outputs medium-to-low voltage levels, commonly in the range of 11 kV or 33 kV.

- Frequency: The standard operating frequency is 50 Hz or 60 Hz, based on regional standards.

- Cooling Method: Usually utilizes ONAN (Oil Natural Air Natural), ONAF (Oil Natural Air Forced), or OFAF (Oil Forced Air Forced) systems for efficient heat dissipation.

- Impedance: Specifies the percentage impedance, generally between 6-15%, influencing voltage regulation and short-circuit performance.

- Tap Changer: Includes an on-load or off-load tap changer for voltage adjustments.

- Efficiency: Designed with high efficiency, often exceeding 98%, to minimize energy losses during operation.

These specifications help ensure the transformer performs reliably under diverse loads and operating conditions.

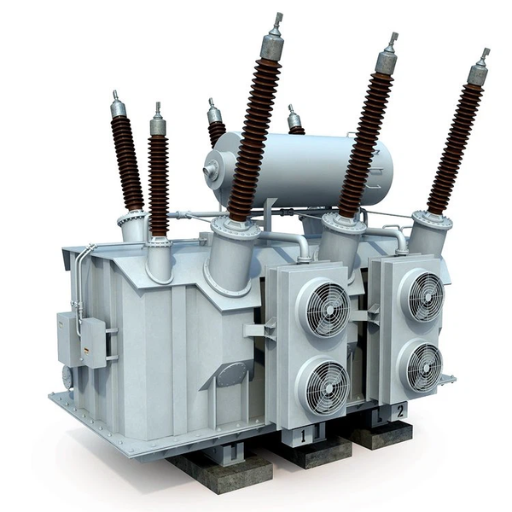

Key Features and MVA Transformer Specifications

- High Voltage Handling: MVA transformers are engineered to manage high voltage levels efficiently, ensuring seamless power transmission in industrial and utility applications. Voltage ratings typically range from 11 kV to 765 kV or higher, depending on specific system requirements.

- Optimal Cooling Systems: Equipped with advanced cooling mechanisms such as ONAN (Oil Natural Air Natural), ONAF (Oil Natural Air Forced), or OFAF (Oil Forced Air Forced) to maintain temperature stability and improve thermal performance under heavy loads.

- Robust Core and Winding Design: Built with precision-engineered cores and windings for high magnetic efficiency and reduced core losses. Copper or aluminum windings are commonly used for their conductivity and durability.

- Load Tap Changer (LTC): Features an on-load or off-load tap changer for dynamic voltage regulation, enabling flexible operation across varying load conditions.

- Impedance Matching: Transformers maintain optimized impedance levels (typically 6-15%) to balance voltage regulation and fault current limitation.

- High-Efficiency Ratings: Designed for efficiency levels exceeding 98%, achieving minimal operational energy losses and significant savings in power systems.

- Safety and Durability: Incorporates protection mechanisms like Buchholz relays, pressure relief devices, and temperature control systems to enhance operational safety and extend the transformer’s lifecycle.

These key features, combined with precise MVA ratings tailored to application needs, make these transformers an integral component for high-performance and reliable electrical systems.

The Role of Cooling Systems in High-Capacity Transformers

The operational efficiency of a high-capacity transformer is maintained by critical cooling systems, which also prevent overheating overheating from electrical losses. These systems help maintain the transformer’s temperature under limit, enabling performance consistency and service life maximization. Common cooling techniques are oil-immersed cooling (such as ONAN, ONAF, or OFAF) and air-cooled systems (like AN and AF). Every type of cooling is picked based on the transformer’s size and capacity, as well as the particular application’s requirements. If there is inadequate cooling, thermal stress could damage insulation, reduce efficiency, and, ultimately, lead to failure. Effective mechanisms of cooling are crucial for reliable transformer operation.

How Does Transformer Size Affect Capacity and Efficiency?

In transformer construction, size relates directly to its effectiveness and efficiency through the winding configuration and core design. An increase in transformer volume typically indicates an increase in capacity because the transformer can accommodate larger cores and have more extensive windings, which increases the power load that the transformer can handle. However, larger cores and extensive windings also increase efficiency losses due to the increase in size which, if not controlled, may adversely impact efficiency. Lower volume transformers tend to be more efficient at low loads although they suffer from excessive relative losses, a capacity constraint, and increased demands. The design of a transformer should aim to balance the increase in size and the load to enhance capacity and efficiency.

Exploring MVA Transformer Dimensions and Their Impact

Transformer size and efficiency are influenced by several core factors, including material selection, load operation, and energy loss management. Larger transformers with high MVA ratings are designed to handle greater power loads due to increased core cross-sections and advanced winding configurations. However, this scaling can lead to higher core (no-load) and copper (load) losses if materials such as silicon steel or copper are not optimized for conductivity and magnetization efficiency.

To balance size and performance, modern transformer designs employ efficient cooling systems (e.g., oil or gas cooling) and insulation materials, which mitigate losses caused by overheating. Efficiency also depends on operational load levels, as transformers are most efficient when run close to their rated capacity. Undersized transformers can suffer from overloading, reducing service life and operational safety, while oversized units may operate under partial loads, incurring higher proportional losses.

The ideal transformer dimensions and capacity are determined by application requirements, ensuring a balanced trade-off between size, efficiency, and long-term operational stability.

The Importance of Transformer Weight and Installation

Transformer weight plays a critical role in its design, transportation, and installation processes. Heavier transformers typically indicate larger core sizes or added elements like cooling systems and insulation materials, which contribute to better efficiency and performance. However, transportation and installation of heavy units require specialized equipment, careful planning, and often additional infrastructure investments, such as reinforced bases or extended delivery timelines.

Proper installation ensures not only operational safety but also the longevity of the transformer. Factors such as foundation stability, ventilation systems to dissipate heat, and vibration mitigation are essential. Weight considerations also affect placement decisions; transformers installed on rooftops or within compact facilities must match structural load limits to prevent damage. Therefore, balancing transformer weight with performance and site-specific requirements is a fundamental aspect of achieving both reliability and efficiency in power distribution systems.

How Do Different MVA Transformers Compare?

When comparing different MVA (Mega Volt Ampere) transformers, several key factors must be evaluated to determine their suitability for specific applications. High MVA transformers typically handle larger loads and are used in high-capacity systems such as power plants and industrial facilities. These transformers often come with advanced cooling systems, such as forced oil or air cooling, to manage the significant heat generated during operation.

Lower MVA transformers, on the other hand, are ideal for smaller-scale applications like residential or commercial buildings where the load requirements are moderate. They are generally more compact, easier to install, and incur lower initial costs and maintenance demands. Additionally, efficiency levels, voltage regulation, and impedance characteristics vary across MVA ratings, making it crucial to align the transformer’s specifications with the system’s operational demands and performance criteria.

Comparing 120 MVA to 600 MVA Transformers

When comparing 120 MVA transformers to 600 MVA transformers, there are several distinctions to consider. A 120 MVA transformer is designed for medium-scale applications, typically used in regional distribution systems or industrial facilities. It is smaller, easier to install, and requires less investment in initial costs and ongoing maintenance. On the other hand, a 600 MVA transformer is engineered for large-scale transmission networks and high-capacity systems like power plants. This transformer handles significantly higher loads and often includes advanced cooling technologies due to the substantial heat generated during operation. Efficiency, voltage regulation, and impedance also differ, with the larger transformer requiring precise adjustments and monitoring to ensure optimal performance under heavy loads. Ultimately, the selection should be based on the specific demands of the application, balancing capacity, efficiency, and cost considerations.

Understanding the Price and Efficiency Factors

When evaluating the price and efficiency of transformers, several critical factors come into play. Price is influenced by transformer capacity, design complexity, materials used (such as copper or aluminum windings), and the presence of advanced technologies like on-load tap changers or enhanced cooling systems. Generally, a higher-rated transformer, such as a 600 MVA unit, incurs significantly greater costs due to the increased size, intricate design, and higher-grade materials required to handle elevated loads.

Efficiency, meanwhile, is determined by core and copper losses, which vary depending on the transformer’s construction and operational load. A 120 MVA transformer typically demonstrates higher efficiency under moderate loads, making it more cost-effective for smaller applications. Conversely, the 600 MVA transformer achieves optimal efficiency at higher loads, as it is engineered for intensive, large-scale operations. To balance price and efficiency, the total cost of ownership (including initial investment, operating costs, and maintenance) should be analyzed. Selecting the right transformer requires aligning these factors with load demands, energy loss tolerances, and long-term operational goals.

Choosing the Right Transformer Manufacturer for Your Needs

When selecting a transformer manufacturer, it is essential to evaluate key factors such as product quality, industry expertise, and service capabilities. Start by assessing the manufacturer’s certifications and compliance with international standards, such as ISO 9001 or IEC, which indicate a commitment to quality and reliability. Next, review their track record in producing transformers suited to your specific application, whether for industrial, utility, or renewable energy purposes. Manufacturers with diverse portfolios often have the flexibility to meet specialized needs.

Customer service and after-sales support are equally critical, as transformers require regular maintenance and potential troubleshooting over their lifecycle. Choose a manufacturer that offers comprehensive warranties, technical support, and readily available spare parts. Additionally, consider their ability to customize designs, as well as their production timelines to meet project deadlines.

Finally, compare cost and long-term value by analyzing initial pricing, efficiency ratings, and maintenance costs. A manufacturer that balances competitive pricing with high-performance products will provide the best return on investment. Leveraging customer reviews, case studies, and detailed product specifications can further assist in making an informed decision.

References

Frequently Asked Questions (FAQ)

Q: What does the MVA rating mean in a transformer?

A: The MVA rating, or megavolt-amperes, refers to the apparent power a transformer can handle. It represents the product of voltage and current without considering the power factor, indicating the transformer’s capability to carry electrical power.

Q: How does a 120 MVA transformer differ from a 200 MVA transformer?

A: A 120 MVA transformer has a lower capacity to handle electrical power compared to a 200 MVA transformer. The difference lies in the amount of power each can handle, with the 200 MVA transformer being suitable for larger power loads, often used in high voltage applications.

Q: What is the importance of a transformer’s nameplate?

A: The nameplate of a transformer provides essential information such as the MVA rating, voltage levels, connection type, and cooling method. This information is crucial for determining the transformer’s suitability for a specific application and ensuring its safe operation.

Q: How do you convert MVA to kVA?

A: To convert MVA to kVA, multiply the MVA value by 1,000. For instance, a 20 MVA transformer is equivalent to 20,000 kVA.

Q: What factors influence the MVA transformer price?

A: The cost of the transformer is influenced by several factors, including its MVA rating, voltage class, type of transformer (such as distribution or power transformer), insulation type, and the MVA transformer manufacturer. Larger and more complex transformers typically have higher prices.

Q: Why is MVA used instead of MW for transformer ratings?

A: MVA is used instead of MW because it represents the apparent power, which includes both real power (MW) and reactive power. This gives a more comprehensive view of the transformer’s capacity to handle a circuit’s apparent power, encompassing all power factors.

Q: What is the typical weight of a 150 MVA transformer?

A: The MVA transformer weight for a 150 MVA transformer can vary based on design and manufacturer specifications, but it typically ranges from several tens to hundreds of tons. The weight is influenced by factors such as the core material, winding design, and cooling system.

Q: How does a transformer’s power factor affect its operation?

A: The power factor affects a transformer’s efficiency and the amount of real power it can deliver. A low power factor indicates high reactive power, which can reduce the efficiency of power transmission and increase losses in electrical systems.

Q: What role does a transformer play in a power station?

A: In a power station, a transformer is an electrical device that steps up or steps down voltage levels to facilitate efficient power transmission and distribution. By adjusting the voltage and current, transformers minimize power losses over long distances.