In electrical systems, the role of the transformers in the transmission and distribution of electricity is critical. But, just like any other mechanical and electrical system, transformers have their own set of problems that can affect their efficiency. One such problem, and perhaps the most relevant one is oil leakage. This article seeks to elucidate the causes of transformer oil leaks, their environmental and equipment ramifications, and corrective and preventive actions that can be taken to mitigate such issues. No matter if you work in the energy industry or simply want to learn more about transformer service, this guide has something for you regarding the intricacies of transformer oil leaks.

What are the common causes of transformer oil leaks?

Some of the most frequent reasons for transformer oil leaks are aging and wearing down of the gaskets, improper sealing during installations and maintenance, and even mechanical stress, which causes cracks around the tank or welds – which is then made worse by thermal expansion straining components. Furthermore, corrosion and aggravated weather conditions can considerably worsen material longevity, which in turn leads to oil leakage. Addressing such issues needs regular attention and maintenance to avoid becoming more pronounced.

How do seal failures lead to transformer oil leakage?

The seal failures put the integrity of a transformer’s oil containment system at risk directly. From my personal experience, even small imperfections in gaskets or welds pose a risk of enabling oil to escape through pressurization. In time, aged seals become less pliable, and poor solutions frequently result in the unilateral fitting of parts. The equipment now has greater chances of breach due to external contaminants like moisture that further worsens the quality of oil. This emphasizes the need for proper seal checks and installations as transforms performance, longevity and maintenance depend on how leaks are avoided.

Can manufacturing defects cause oil leaks in transformers?

Inevitably, these manufacturing defects can result in oil leaks within the transformers. Problems like ill-shaped seals, improperly welded seams, or even misplaced components during the assembly process can contribute to structural weaknesses that, over time, result in oil leakage. Such flaws, if remaining unidentified and uncorrected in the quality control circle, will weaken the transformer beyond repair, beaconing the need for tough manufacturing restraint and rigid quality checking processes.

What role does improper installation play in transformer oil leaks?

I have come across this issue several times in the field, and improper installation is largely responsible for oil leaks in the transformer. Ill-advised manipulations during initial set-up may break seals, gaskets, or fittings, leading to gaps where oil leakage is possible. Also, insufficiently tight bolts, out of alignment parts, or poorly fitted components may cause additional loads creating stress risers which increases the probability of oil leakage. It is important to maintain the dependability of the transformers by refraining from such unnecessary problems which result from not following installation procedures, including company instructions and use of proper personnel.

How to identify a leaking transformer?

Finding a leaking transformer calls for closely observing the unit and looking for oil leaks. Check for oil marks or puddles at the base of the transformer since they are undeniable signs of leakage. Furthermore, consider any odometer damage or discoloration along with an unanticipated drop in oil level of the transformer. Routine maintenance visits combined with the use of diagnostics such as infrared cameras can also reveal leaks in advance so that they can be dealt with before they become too serious.

What are the visual signs of transformer oil leakage?

the most prominent traces of transformer oil leakage are dirtied oil stains or puddles near the bottom of the transformer. These stains are often surrounded by grime and oil. Another strong indicator of a transformer oil leak would be tattered fragmentary gaskets and seals. These degrade over time and allow oil to escape. A swift decrease in the transformer’s oil volume is also one of the many signs to look out for, as it often indicates a leak. Detecting the issue early, along with consistent inspections, using tools such as infrared imaging, are crucial to solving these problems and giving the transformer optimal efficiency.

How does the oil level indicate a potential leak?

In a transformer, decreasing oil levels can suggest oil leakage within the system due to pre-existing cracks or degraded seals and gaskets. Any significant depreciation should be supplemented with prompt diagnostic investigations to avoid cooling or insulation operational impediment or equipment failure, especially in light of what oil is crucial to a transformer.

Can unusual sounds or hum suggest a leaking transformer?

strange noises or irregular humming can at times suggest problems with the transformer, albeit not confirming a leak. These noises are often associated with internal electrical or mechanical failures, including but not limited to, loose parts, saturation of the core, and vibrations of the windings. When combined with other indicators such as lowering levels of oil and physical damage, they could suggest a leak. It is necessary to ensure that complete checks and testing are performed to establish the appropriate problems and provide a solution in a timely manner.

What are the consequences of transformer oil leaks?

The consequences of transformer oil leaks are serious and can include decreased insulation functionality, overheating, and damage to internal components. Over time, this leads to a reduced oil level which makes it impossible for the transformer to effectively disperse heat and lower the chances of a malfunction or fire. Moreover, if these are not taken care of quickly, they may create environmental pollution as well as legal fines. In order to ensure reliability, safety, and compliance with standards, one must address oil leaks immediately.

How does oil leakage affect transformer insulation?

An oil leak directly affects the transformer insulation by reducing its effectiveness, therefore impacting the performance of the transformer. From my field experience, after oil leaks occur, the oil level declines and its insulating attributes are lost, which in turn raises the risk of overheating and electrical failure of the transformer. Insulation loss integrity results in the paper insulation aging at an accelerated pace, which in turn leads to decreased equipment lifespan. Oil level maintenance is crucial for the transformer’s insulation system and guarding the insulation’s reliability for an extended duration.

Can a leaking transformer pose safety risks?

Absolutely, a leaking transformer can create specific safety hazards, and I will elaborate on this issue step by step in a manner that is intuitive.

- Fire Hazard: A leak can expose the insulation of the transformer’s internal systems, which can lead to a short circuit if the electrical insulation fails. This shorts out the internal components of the transformer, causing severe damage to the device and endangering those working nearby due to possible electric shocks or arcing.

- Electrical Failures: An unattended leak can allow transformer oil to escape underground or into water systems, creating an ecological hazard. Additionally, these spills endanger local ecosystems which can create compliance challenges along with cleanup expenses.

- Environmental Concerns: A transformer failing to maintain proper oil levels is subject to catastrophic, and in some cases, instantaneous failures. This not only affects the equipment, but also critical systems which rely on the switchboard or electric supply.

- Operational Hazards: Insufficient oil in a transformer results in the sudden failure of the system, which causes significant disruptions to the power supply. The transfeormer should be carefully monitored, as this type of oil deficiency can severely impact multiple pieces of vital systems that depend on electricity.

To prevent these issues from expanding, one must regularly maintain and inspect the equipment. Keeping an eye on oil levels, detecting leaks, and putting repairs on faulty systems not only enhance a transformer’s lifespan, but also enhance safety from the hazards.

What environmental impacts can transformer oil spills cause?

I can tell you that transformer oil spills can be ecologically damaging if not responded to quickly. They have the ability to pollute the soil and water around the area, which impacts whole ecosystems and communities. If the oil seeps into the groundwater, it becomes undrinkable and puts marine animals at risk. What’s more is that the oil spill clean up can be challenging and very costly as well. This is precisely why preemptive measures need to be taken to contain the spill and prevent it from getting out of hand. Containment systems can significantly reduce damage to the environment if they are deployed quickly.

How to repair a leaking transformer?

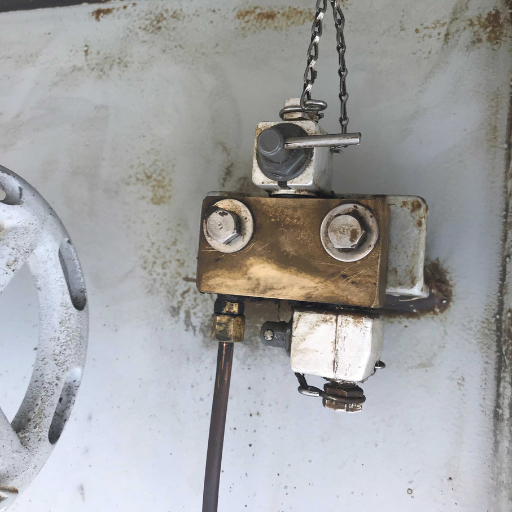

- Inspect and Identify the Leak: With a thorough examination of the transformer, find the precise location of the leak as this usually is located round the gaskets, seals, or welds.

- Depressurize and Isolate the Transformer: Make certain that the transformer is turned off and it is no longer part of the electrical circuit. If there is a possibility of further leakage taking place during the repairing phase, depressurize the device.

- Drain the Oil (if required): In case the leak is serious or lies close to vital parts, remove the oil so that its level is well below the leak point and ensure it is kept carefully for later usage.

- Clean and Prepare the Area: Remove any surface oi,l especially the top surface from the leak area so as to assist in sealing and ensure a rough clean all the area so that any other dirt or residue does not interfere in the repair work

- Replace or Repair the Faulty Component: Remove old gaskets, seals, bolts or welds as required and replace them. If the leak is minor, then special transformer seal and epoxy materials can be used to seal it.

- Refill and Test for Leaks: After repairs, replace the oil with clean filtered oil, without any contaminants. Prior to returning the transformer to service check for leakage.

- Monitor After Repairs: Observe the transformer closely in the days to follow after putting it back into service for any leakage issues that may arise.

So long as these steps are fully met, you will be able to safely and reliably operate while resolving transformer leaks.

When should you contact a professional for transformer leak repair?

I recommend finding professional help in fixing transformer leaks when the situation involves complex problems like severe gasket breakdowns, massive oil spillage, or leakage in very deep seated locations. Furthermore, strange overheating, weird noise, and powered-down intervals along with the leak, if noticed must be nipped in the bud by seeking professional help immediately. Ordinarily attempting these repairs without prior knowledge is dangerous to the safety of the user and inhibits the functionalities of the transformer. When dealing with huge industrial transformers, or case scenarios entailing sophisticated tools and devices, always look for professional help for accurate and long lasting results.

What are the steps to temporarily seal a minor transformer oil leak?

Adopt the appropriate safety measures to ensure a minor transformer oil leak is sealed temporarily. The steps which follow should be approached with care.

- Identify the Leak: Like an investigator, pinpoint the minor leakage with a measured degree of caution, and examine the area scrupulously.

- Clean the Area: Eliminate any form of oil or obstruction that may tamper with the temporary seal on the leak by scrubbing the area with a clean dry rag.

- Apply Epoxy or Sealant: Seal the leak with part epoxy or a high-quality epoxy resin sealant that is specially formulated to resist transformer oil. Make sure that the sealant can withstand transformer oil and that it is recommended for that purpose.

- Allow Curing Time: Observe and follow the manufacturer’s instructions with regards to the curing time of the sealant. Make sure that the seal has fully set and will serve as an efficient barrier.

- Monitor the Repair: Until a permanent fix can be made, monitor and wait for the area that was sealed to show leakage or wear and tear.

Never forget that this is a makeshift solution and an expert’s repair or replacement needs to be sooner than later to ensure the transformer’s safety and dependability.

How is the process of replacing faulty components in a leaking transformer?

skill and accuracy are needed to fix leaking components on a transformer. The first step would be isolating it. First, I need to turn off the transformer and disconnect it from the power source. After that, I slowly pump out the transformer oil to get to the internal parts while avoiding contamination. Then I will check for broken and replace them with seals, bushings, or gaskets that will pass the criteria. After everything is set, I put in oil that has been filtered to ensure that it meets all dielectric requirements. After the repair is done, the transformer will go under a rigid check and test to confirm the structural soundness of the repair. These steps in order will reduce any issues that occur while also maintaining the balance between safety and productivity.

Can transformer oil leaks be prevented?

Certainly, proactive maintenance approaches and effective sealing techniques minimisae the posibility of a transformer oil leaks. In conjunction with regular inspections, the use of high-grade gaskets and seals aids in identifying wear and damage in advance to greatly limit leaks. Also, adequate care during installation and maintenance aids in maintaining the integrity of connections in the long-run.

What regular maintenance can help prevent transformer oil leaks?

Maintaining an efficient operation of transformers necessitates constant monitoring, which, in my opinion, can minimize chances of leakage of oil from the transformers. First, I conduct routine visual examinations of the seals, gaskets, and their associated fittings to assess if there are any signs of undue stress. I clean the transformer and its fittings routinely, which mitigates chances of contaminants adulterating the seals. Additionally, periodic testing of the oil assists in identifying moisture intrusion or quality degradation among other issues. Lastly, due maintenance of the bolts and fittings to the suggested torque levels enables a constant secure situation, therefore lessening chances of leakage from the transformer over time. Putting these steps into action regularly helps in the efficient function of a transformer devoid of leaks.

How does proper installation ensure leak-free transformer operation?

Correct installation creates a strong transformer’s operational foundation, leading to leak-free transformer performance. The use of quality materials, precise component positioning, and adherence to manufacturer’s specifications along with correct torque application to all fittings minimizes risk levels that can result in leaks. Environmental factors such as proper sealing methods and site suitability for long-term stability, when combined with these practices, form a strong and rigid system.

What role do compatible materials play in preventing transformer leaks?

I have learned that the appropriate selection of materials is vital in avoiding transformer leaks. For tight seals and longevity to ensure gaskets do not leak over time, the mechanical and chemical compatibility of materials with the design of the transformer must be appropriate. For instance, gaskets made from incompatible compounds will leak with time. The selection of materials that are proven to be compatible under different operational and environmental conditions gives a higher guarantee to mitigate voids and maintain the system’s integrity.

When should you report a transformer oil leak to your utility company?

If you discover a leak in transformer oil, it is essential to notify your utility company right away. Reporting leaks as soon as possible is essential for mitigating potential environmental risks in relation to power system safety, equipment damage, and system reliability. Acting quickly enables the utility company to deal with the problem proactively, before it snowballs into more severe complications.

How to contact your local utility or power company about a leaking transformer?

To make contact with the utility or power company that services your area in regard to a leaking transformer, I suggest you make powerful moves urgently and undertake the steps that follow. First, you need to look for the contact details of your utility company, which would most likely be present on your utility bill or their official webpage. Almost all companies have emergency hotlines or systems for customer service that deal with equipment problems. When calling, make sure you give the customer service representative information such as the more specific location of the transformer, what type of leak it is, and if there are any marring damages. If possible, take pictures as the company would benefit from the proof since it would allow them to assess the situation much simply. Always keep safety first by staying far from the transformer until experts are able to come and deal with the situation.

What information should you provide when reporting a transformer oil leak?

Sharing specific information will help effectively rectify a transformer oil leak within the least possible time. In the service experience that I have gathered, here is what I think you should provide:

- Exact Location – state as clearly as you can. Give the address of the leaking transformer or nearby notable landmark. This is necessary so that the utility company can find the problem area without wasting any time.

- Description of the Leak -Explain what you observe. If there is oil leaking from the transformer, state whether it has formed a pool, is dripping or is seeping through slowly. This will be helpful in determining the extent of the problem.

- Visible Damage – Check the transformer for external signs of leakage like rust marks, cracks, breaks, or even holes. If there is an audible buzzing sound, this may need to be noted.

- Surrounding Environment – Comment on the vicinity of the transformer. Does it lie along a road, next to a structure, or adjacent to a water body? This is crucial in evaluating the possible ecological or safety hazards the area poses.

- Photos or Videos (if safe to capture) -they are useful in unclogging a malfunction in the device effortlessly. Always maintain a cautious distance for safety and only take photographs when it’s secure to do so.

- Contact Information – State your full name and a trusted mobile telephone number. In this way, utility company representatives have means to contact you in case further explanation is needed.

Furnishing this information enables the utility team to take proactive measures to mitigate any risks. Bear in mind to take precautions when near any leaking machinery and always maintain a safe distance for your own protection.

DIY vs. Professional: Who should handle transformer oil leaks?

Transformer oil leaks should always be handled by professionals. While minor leaks may appear manageable, addressing them requires specialized knowledge, tools, and safety equipment to prevent further damage or environmental contamination. Professionals are trained to assess the severity of the leak, adhere to industry safety standards, and perform repairs or replacements efficiently. Attempting a DIY fix can inadvertently worsen the issue, pose safety risks, or violate regulatory compliance. When it comes to transformer oil leaks, entrusting the task to qualified experts ensures safety, reliability, and adherence to environmental guidelines.

What are the risks of DIY transformer leak repair?

As I have seen in my work, the consequences of trying to fix a transformer leak on your own can be highly detrimental. First and foremost, there is the threat to one’s personal safety; without the proper training, dealing with high-voltage machinery and hazardous oil could potentially result in serious injuries or in the worst-case scenario one could lose their life. Additionally, the repair attempts may do the opposite and worsen the leak more, which further destroys the transformer and makes the waiting period longer. There is also considerable damage to Mother Nature to think about. If the required professional attention and legislation are not met, oil from the transformer can pollute the earth and the water. In the end, these risks exceed any possible savings one may have from doing the work themselves, which is why outsourcing to skilled experts is always the best and most efficient choice.

When is it necessary to call in electrical professionals for transformer leaks?

For electric transformer leaks, it is of utmost importance to notify the professionals immediately after the leak is evident. Failure to call an expert in time might result in severe safety issues, damage the transformer more, or cause environmental disturbances. Such qualified professionals are equipped with the right set of skills, tools, and other pertinent information essential for analyzing and solving the problem while following legal industry norms.

Reference

- Transformer Oil Leaks: Guide to Troubleshooting and Repair – Discusses causes like manufacturing defects, corrosion, and external damage.

- How to Spot and Repair Transformer Oil Leaks – Covers causes such as poor welding, material defects, and temperature variations.

- Transformer Oil Leaks (Belzona) – Explains issues like corrosion and faulty welds leading to breakdowns in components.

Frequently Asked Questions (FAQs)

Q: What are the main causes of transformer oil leaks?

A: Transformer oil leaks are usually caused by various factors, including aging equipment, physical damage, faulty seals, or excessive pressure. Cracks in the radiator tubes, loose valves, or deteriorating gaskets can also lead to mineral oil leakage. Environmental factors like extreme temperatures or electromagnetic stress can contribute to these issues as well.

Q: What are the consequences of a transformer leaking oil?

A: A transformer leaking oil can have serious consequences, including reduced electrical insulation, overheating, and potential equipment failure. It may lead to decreased voltage regulation, compromised safety, and environmental contamination. If left unaddressed, oil leaks can cause the transformer to shut off, resulting in power outages and costly repairs.

Q: How can I identify a transformer oil leak?

A: To identify a transformer oil leak, look for visible oil stains or puddles around the base of the transformer, radiator, or other components. You may also notice a decrease in oil levels during routine inspections. In some cases, you might smell a distinct odor or see oil droplets on the transformer’s surface, especially after rain.

Q: What should I do if I discover a transformer leaking oil?

A: If you discover a transformer leaking oil, it’s crucial to report the leak immediately to your local utility company or a qualified electrician. Do not attempt to fix the leak yourself, as transformers deal with high voltage electricity and can be extremely dangerous. The utility company will assess the situation and may need to shut off the transformer to ensure safety and prevent further damage.

Q: Are there any quick solutions to stop a transformer oil leak?

A: While it’s not recommended to attempt repairs yourself, professionals may use quick sealing methods for minor leaks. These can include applying specialized sealants, tightening loose fittings, or using temporary patching materials. However, these are typically short-term solutions, and a proper repair or replacement should be conducted to ensure long-term safety and efficiency.

Q: How can transformer oil leaks be prevented?

A: To prevent transformer oil leaks, regular maintenance and inspections are crucial. This includes checking and replacing gaskets, seals, and valves as needed. Proper oil level management, using high-quality mineral oil, and ensuring the transformer operates within its designed stress limits can also help prevent leaks. Additionally, protecting the transformer from physical damage and extreme weather conditions can prolong its lifespan and reduce the risk of leaks.

Q: What are the environmental impacts of transformer oil leaks?

A: Transformer oil leaks can have significant environmental impacts. The mineral oil used in transformers can contaminate soil and water sources if not contained properly. This can harm local ecosystems, wildlife, and potentially enter the food chain. Additionally, cleaning up oil spills can be costly and time-consuming, often requiring specialized equipment and procedures to mitigate environmental damage.

Q: How often should transformers be inspected for potential leaks?

A: The frequency of transformer inspections depends on various factors, including the age and condition of the equipment. Generally, it’s recommended to conduct visual inspections monthly and more comprehensive checks quarterly or annually. However, for critical or high-risk transformers, more frequent inspections may be necessary to ensure optimal performance and detect potential leaks early.

Q: Can transformer oil leaks be repaired, or does the entire transformer need to be replaced?

A: Whether a transformer can be repaired or needs replacement depends on the severity and location of the leak. Minor leaks in accessible areas, such as radiator tubes or valves, can often be repaired by welding, using sealants, or replacing specific components. However, if the leak is extensive or affects critical parts of the transformer, a full replacement may be necessary to ensure safety and reliability.

Q: I’m interested in getting into the trade and becoming a lineman. Are there any top posts about getting started in this field?

A: While this question isn’t directly related to transformer oil leaks, it’s great that you’re interested in becoming a lineman. To get started, please read industry publications and online forums for top posts about getting into the trade. Keep in mind that many training programs and apprenticeships are only permitted during weekends or specific times. It’s a challenging but rewarding career that requires knowledge of electrical equipment, safety procedures, and hands-on skills.