The furnace transformer is an important part of the heating system since it controls the voltage needed to power the various mechanisms inside the furnace. This part is crucial as any wear on it will result in an inefficient or nonworking furnace which can lead to heating problems and expensive repairs in the future if it is not fixed. In this article, you will learn about the relevant symptoms that a furnace transformer exhibits when it is falling apart and whether a replacement is required. You can make proactive decisions that will help keep your heating system efficient and effective by being aware of these warning indicators.

What is a furnace transformer and what does it do?

An electrical component used in the operation of a furnace is known as a furnace transformer, it operates by adjusting the voltage that is required for the furnace to function as required. What this piece of machinery does is convert high voltage emanating from the mains supply to a lower one which is generally 24 volts, this lower voltage suffices to power up the internal sections of the furnace, for instance, the thermostat, control circuits among others. Failure to maintain the proper levels of volts can lead to damage to the system, therefore this process is extremely important.

Understanding the role of a transformer in HVAC systems

Transformators are devices that are quite common within an HVAC system and assist in maintaining the equipment’s safe working operation due to deck the electrical energy to the required amount or voltage levels. It commonly reduces an input high voltage of 120V or 240V electrical supply voltage to the most preferred 24V secondary voltage. This is because other HVAC units such as the thermostat, relays and control boards work with low voltage and such helps reduce the chances of incidents occurring.

The primary function of the transformer includes providing electricity to the control systems of appliances such as the furnace, air conditioners or heat pumps so that they can perform appropriate actions such as heating, cooling and also turning on the fans. Furthermore, the transformer circumvents the circuit by blocking the impact of the high voltage which would affect the more delicate HVAC components. In the absence of the transformer, for instance, electrical power loss to the thermostat can occur that leads to erratic behavior of the system which is not normal, an event that should forewarn the user of the need for an immediate intensive examination and replacement of the transformer so that the normal HVAC system operation is resumed and was not damaged in any way.

How a furnace transformer regulates voltage

A furnace transformer steps down high voltage electricity coming into the HVAC systems to a usable one, usually 24 volts meant for the thermostat and control circuits. I make sure that it delivers a robust power supply to critical parts which enables accurate heating, cooling, and fan controls. If the transformer suffers damage or failure I would look out for climatic discomfort due to thermostat nonworking, or even total blackout of the system. Timely reaction is mandatory as a defective transformer may ruin the whole unit of HVAC and over time may become detrimental if ignored. Rewrite this text, making sure that the core meaning has always been retained. Avoiding Plagiarism in the Rephrased Text should still be considered.

Types of furnace transformers: 120V, 240V, and 24V

120V Furnace Transformers

The 120V furnace transformer steps down the standard 120V power supply for light commercial or residential wiring systems to 24V, which is used to power control contraptions such as thermostats, relays, solenoids, etc. This type of transformer has been used more often in systems or houses in which 120V is the main input voltage. Some key parameters include input voltage specifications which is 120V AC, output voltage specifications which is 24V AC and power ratings between 20 to 75 VA (Volt-Amperes) in conventional terms. These transformers can short circuit or become overloaded so proper installation and fuse protection is necessary to prevent failure of these transformers.

240V Transformer for Furnace

240V furnace transformers are particularly utilized in modern systems or areas where 240V supply is common. Also, in a similar manner to their 120V cousins, they step down the incoming voltage to 24 volts for safe control operations. However, these are more common in high performance systems with larger heating or cooling capabilities, particularly in commercial settings. Their technical data typically includes 240V AC supply voltage, 24V AC output voltage, and a power capacity of between 40 to 100 volt-ampere. During installation, proper ground installation and connection type compatibility checks are necessary to ensure no electrical danger is posed.

Transformers For 24V Furnaces

They say 24V transformers can only perform one function namely reducing the voltage level but this is a complete lie. What is true however is that these transformers are instrumental in making 24V control circuits possible in different models of furnaces. It is also important to note, that while the statement says 24 volt transformers, it should be regarded as the secondary voltage of the transformer, which sometimes confuses individuals, inversely proportional to the primary voltage of a 120:240V transformer. Not only this but also that their primary load barring the rating assists with the load requirements of a 20 – 50 VA supply. Also because of the high voltage, they should be checked regularly to mitigate regular maintenance shutdowns from natural wear and corrosion.

Needless to say, when a furnace system is being installed, attention and focus on a correct transformer to voltage and VA matching is truly paramount to secure efficacy and reliability through the durability of the system in use.

How do I know if my furnace transformer is bad?

There are several ways to know that there is a problem with the furnace transformer. One is the furnace not provided with invigilating power and this can end up meaning the HVAC will not initiate or function properly. Also, when the transformer suffers some internal fault then abnormal sounds like hum or buzz will be heard from it. This problem has been confirmed by some electrical tests – when a multimeter was used to help measure the output voltage of the transformer and matched it against the rated specification. Such divergences in ordinates of output or even nonexistence of voltage could lead to the conclusion that the transformer is most probably damaged beyond repair needing replacement instead. Constantly blown fuses and reset switches might also be another red flag for transformer issues.

Common symptoms of a faulty furnace transformer

Unusual Noises

Persistent humming, buzzing, or clicking sounds can be indicators of faults in the transformer.

Voltage Irregularities

It is advisable to measure the voltage of the output using a multimeter. This is essential for every transformer, for instance, when a furnace transformer is in question, the specification states that the secondary output voltage should not fall outside the range of 24V to 28V AC. If there are great changes observed, then it means there is a fault in the system.

Frequent Blown Fuses or Tripped Breakers

In the case of fuses that have to frequently be replaced after blowing off or circuit breakers that within a short while trip, it could be indicative of a high electrical load or a transformer short circuit. As part of now, these statements must not be generalized and such phenomena should first be confirmed as not created by problems with external electricity supply lines.

No Power to Connected Components

If the output voltage to be delivered is normal but there still isn’t any bounded thermos, then the control board must be faulty as the transformer appears to also be faulty.

Burnt Odor or Visible Damage

Smelling burnt materials while the transformer is in use or seeing melted coverings and burn marks on or around the transformer is a sure sign to not only stop using the transformer but also to completely replace it due to a critical failure.

Confirmation of the Transformer being faulty as the root cause should be accompanied with the exclusion of wiring and load complications that could have arisen externally.

Testing your furnace transformer with a multimeter

To begin testing the furnace transformer with a multimeter, I start by turning off the circuit breaker supplying the furnace in the first place to not endanger myself in the process. After this, I look for the transformer that is usually attached to the control board and in it, I identify the primary and the secondary terminals. Next, using the AC voltage setting on the multimeter, I turn to the primary side and take my reading which should be around 120V. Next, I take the secondary side reading which is supposed to take an output of around 24V AC. If the voltages do not correspond correctly, I reason that the transformer has a defect and needs to be replaced. Further, I make use of the multimeter’s ohm setting to confirm whether any open circuits exist while testing continuity across the windings. These figures of 120V for the primary and 24V for the secondary are operating norms provided for approximately all household furnaces but it is always advisable to check the specific details for a specific model.

When to call a professional HVAC technician

Irregular readings of voltage that are not resolved through normal troubleshooting measures, or lack of continuity across the windings are indicators that it is time to call an HVAC technician. An HVAC professional should also be consulted if a person is not sure about dealing with electricity, or if the transformer and these wires seem to be damaged in one or more ways. It is about safety; such qualified technicians will be able to determine the cause of the failure with great precision and fix the problem while abiding by all requirements of the sphere.

Can I replace a furnace transformer myself?

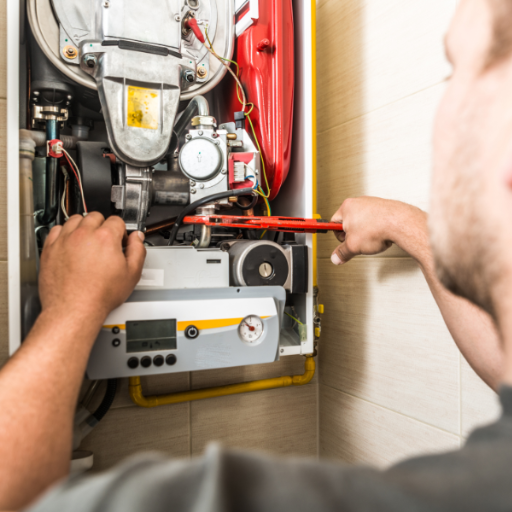

Yes, you can replace the furnace transformer on your own, however, you must first understand a few elements regarding electrical systems and the heating, ventilation and air conditioning (HVAC) system. The first essential point to know is the specific type and the model of transformer that is required to be replaced. You can then check your workstation if you have the necessary safety gear and the required tools. Always remember to unplug the furnace to reduce the chance of electrical shock and then proceed to follow the manufacturer’s written diagrams very closely. But if that is not the case, it is better to get the help of an expert in HVAC systems to assist you in the replacement.

Safety precautions when working with electrical components

When carrying out tasks involving electrical components, it is important to follow safety protocols to avoid accidents, injuries or loss or damage of equipment. First and foremost, make sure to isolate the power completely before performing any work. In instances where it is not possible to switch off any part of the circuitry, the use of a lockout/tagout (LOTO) system is recommended so that the source does not get accidentally re-energized. Insulated tools should be used along with personal electrical protective equipment (PPE) such as the use of rubber-soled boots, safety goggles and gloves which are resistant to electrical shocks.

Even if power is thought to be off, it is good practice to check with a multimeter or similar device that there is no voltage before making contact with components. Whenever there is a possibility of having capacitors or other elements discharged that can contain energy after being powered, ensure that they are de-energized before any such work is carried out. The working environment should be dry and clean and devoid of any materials or products that are capable of transmission of electricity. Furthermore, working near water or during wet conditions must be strictly prohibited.

Have a comprehensive understanding of the electrical system, more specifically the setup in which the wires are configured and the specifications of the components. Do not attempt to exceed the amperage rating of any circuit or install components that are not of the required type since overheating and burning out can happen as a result. Also bear in mind that where there is a high voltage, always make sure to stay within OSHA or local standards’ recommended safe distances from any electric wires or devices in use.

In the end, do only the work that is within your training and experience. For complicated systems or high-voltage works, consult a licensed electrician or a technician to comply with regulations and minimize risks.

Step-by-step guide to replacing a furnace transformer

Switch-off the power

It is very important to never forget to turn off the load on the main circuit breaker or disconnect the switch. The power can be confirmed to be of with the use of the multi-meter check maximum voltage at the terminals of the furnace.

Get to the transformer

A control board or electrical area should have a furnace transformer which can be found by searching in such spots. If you are unable to find it, check the specifications of the furnace in its manual.

Take note of the various wire connections

It is taken as a good practice to take a photograph or sketch the wiring system of the transformer to ensure that the attachment is done as described. The importance of this step is to avoid making wiring errors during reattachment.

Remove the old transformer

Scooping out mounting screws helps unplug wires that were attached to the old transformer and afterward allows disconnection of the old transformer through a set of screwdrivers or pliers.

Put the new transformer in place

As the new transformer is attached to the old one’s frame, wires are also put in the fuse, reflecting the same position as before and are said to be replaced.

Tie off the wirings after verifying all connections

Cross-checking all connections minimizes the risk of accidents and ensures all components are fasted in their appropriate places. To prevent wires from easing back and trying to stray away from their position a good hiding place is ensured in which no movement from the wires or contact with hot surfaces can happen.

Re-establish power and check the operation of the new transformer

Switch on the power at the circuit breaker and verify the proper operation of the new transformer by turning on the furnace. Check for any electrical faults, strange sounds, or malfunctions.

The described steps guarantee a safe and operative furnace transformer replacement avoiding risks and assuring the proper functioning of the system.

When to seek professional help for transformer replacement

If you are confronted with the following problems, don’t hesitate to contact an expert that will help you out: Lack of Technical Expertise If your knowledge of electrical systems or experience of handling a transformer replacement stands null, then better seek the assistance of an expert and licensed HVAC to avoid probable threats. Complex electrical confusions When systems possess intricate and complex wiring, and other additional components, it is deemed essential that other people level up their knowledge to avoid faulty wire arrangement or in the worst scenario, unit damage. High voltage concerns When we talk about transformers, a typical voltage range of 24V to 240V is what is found. The range is however dependent on the system. But failure to cogitate over these can lead to more serious consequences- death or equipment failure to say the least. Reoccurring transformer failures Instances in which the… Transformers! Now we bring in the failsafe! Recurrent instances of the transformer failing suggest that there is a volatile situation taking place at the core such as short circuits, wrong voltage supply and so on as preventive measurement; diagnostic tools and technical expertise should be employed to neutralize the threats. Not Sure Of Your Transformer Specifications? Dilemma Of Selecting The Right Transformer There are scenarios when the primary (boner day) voltage rating which is either 120V or 240V and the second (the one that shines most) voltage 24V along with the ampere rating fits your requirement. By contacting an expert, you rest assured that the transformer selected is compatible with your furnace system. By conducting such operations with professionals, you reduce the risks of long term damage from occurring, ensuring that your heating systems are always and remain reliable for a long period.

What are the best replacement transformers for furnaces?

When purchasing a new transformer furnace, it’s important to make sure to get one that is the same as the one that has been removed so that it can function properly. Some of the most reliable options include:

White-Rodgers 90-T40F1

A great transformer, quite popular, with primary voltage 120V, secondary voltage 24 V, and 40VA power output which is sufficient for most furnace models.

Mars 50301

It works with two different primary voltages and 40VA rated secondary voltage which allows it to work with multiple applications.

Packard PCT40

With a 120V primary voltage 24V secondary, it allows praises of 40 VA and gets the customers very satisfied with its usage when it comes to the common furnace appliances.

Honeywell AT140A1000

Used for heavy-duty applications, it can run off both 120 volts and 208-240 volts while allowing the use of 40VA secondary output.

All the above options are guaranteed to work for quite a while, and the compatibility must be ensured by skimming through your furnace. If there is any kind of confusion regarding the installation processes, consider hiring an expert.

Choosing the right voltage and VA rating for your system

Choosing the proper voltage and VA rating for your furnace transformer ensures the safe and smooth operation of the electric ducted furnace. Circuits are primary 120V or 208-240V depending on the systems in use and the secondary voltage is 24V which is the common voltage for most furnace control circuits. The VA (volt-ampere) rating indicates the upper limit of load that the transformer is designed for and is commonly rated as 20VA,30VA or 40VA in HVAC practice.

To select a suitable transformer, first check your type of furnace in the user manual or product labels to determine the electric supply voltage required of the furnace. Why do you need to know the input voltage of the system? so that it should be equal to (or less than) the transformer’s primary rating e.g. 120v or 120/240V? Then after that, check the total current draw of all connected parts of the device, for example, the thermostat and control board, and multiply the 24V by amperes to get VA. For instance, if the aggregate current draw is 1.5A, this translates to at least 36VA of transformer rating.

In formulating a comprehensive plan to ensure effective installation of the transformer, make sure you consider the following.

Primary Voltage:110V for single-phase residential systems or 208-240V, dual or more is more common in commercial setups.

Secondary Voltage: 24V in most cases to allow simple integration into other HVAC control circuits.

VA Rating: 20VA for standalone basic thermostats in case of low load systems.

30VA or 40VA is for systems that require higher power like smart thermostats or multi-stage furnaces.

Lastly, always add a safety buffer by choosing a transformer with a slightly greater Vas rating than what you have calculated so that space is left for any extra components that may be added later. For proper installation and testing, do so with a qualified HVAC contractor.

Top-rated furnace transformers on the market

Let’s consider the current set of popular sources; it looks like three transformers for furnaces tend to come top rated frequently:

Honeywell AT140A1000

This unit is a 40VA transformer and is characterized by strong and consistent performance, enabling this product to be used in almost any field, including multi-stage HVAC equipment. All these benefits together with a well-planned construction warrant its wide use by many professionals.

Packard PF42440 With a wide 40VA said to its name and thus a changeable 24V supply, this model can be said to be simple and robust at the same time – easy to install and operate powerfully. It is seen to be best recommended for residential as well as small commercial units requiring good voltage.

White-Rodgers 90-T40F3

This unit is particularly a 40VA unit but its rated voltage is said to stand out given the efficiency and thermal protection it provides. Systems using this unit seem to be reliable over a long time as this system surely lasts.

A good number of professionals and customers alike have rated these transformers high and because of that, they tend to be suitable for most furnace and HVAC devices.

Compatibility concerns for different furnace brands

While comparing the compatibility of various furnace brands, I think it’s wise to understand the key specifications and technical parameters that your system requires. In my study, the most significant ones are the input voltage, the output voltage and the VA rating of the transformer. For instance:

Input Voltage- Depending on the supply voltage, ensure that you would need a fortifying furnace that works either with 120V or 240V input.

Output Voltage- HVAC systems require 24V output to operate as it is the operational voltage for relays and valves and circuit boards.

VA Rating- This rating of 40VA would be dependent with the load carried by the unit for home and other light commercial system so that it will run well without burning out.

Also, be careful with mounting and wiring configurations that differ from one brand to another such as Carrier/ Lennox / Goodman. Such brands as Packard PF42440, and White-Rodgers 90-T40F3 and suchlike work very well with these brands because most of them come with standard voltage output and universal mounting. However, do not forget to always read the user manual or the technical descriptions of your furnace to confirm accurate specifications before you make a purchase.

How can I prevent furnace transformer issues in the future?

To prevent furnace transformer malfunctions, you will need to maintain the system effectively and monitor it closely. Make sure that every electrical link is tight and free of rust. Also, bear in mind that regular monitoring of the transformer is necessary to check if it’s getting too hot or gets damaged which would imply that there is an issue. Transformers typically fail due to overstressing because of sudden surges in demand, so it is prudent to fit a surge limiter to minimize the chances of an explosion. Further, make a point to replace air filters to relieve unnecessary stress on the system while ensuring that the furnace operates at its rated voltage. In conclusion, follow up the manufacturer’s recommended schedule of maintenance and request a professional to assess the system at least once a year.

Regular maintenance tips for your HVAC system

I tend to be quite fussy when it comes to making sure that my HVAC does not run into complications. To manage the HVAC system efficiently, I make sure to check, inspect, and replace the air filters every one to three months since clogged filters can affect the central air systems. I also make it a point to vacuum the vents and check for blockages that can inhibit the free passage of air. I tend to check all electrical connections and use a surge protector to keep the system safe and operating efficiently. All electrical connections are inspected since stability is a concern while using my HVAC. Also, I make sure to see if there is any odd noise or scent that is unusual and to see if it flags bigger issues. My HVAC tends to operate effectively and safely all year round provided I religiously schedule professional maintenance yearly. With all of the attention, I can care for the HVAC system which allows for increased longevity.

Protecting your transformer from power surges

To shield a transformer from inrush energies, it is important to adopt steps that prevent jerks and ensure reliability. In as much as two techniques can be utilized while protecting a transformer; the turn to the implementation of sheltering devices such as surge arresters or lightning arresters. Correct installation of surge arresters will adequately provide a means of increasing the bearing capacity of the transformer. For instance, a well-maintained grounding system captures the excess power surge, ensuring the transformer does not overheat. Implementing the use of voltage regulators and isolation transformers will also help stabilize the power supply. Such normalization protects the power system from risks associated with imbalances which includes general destruction of the equipment. In tandem with the previously mentioned measures, installing and deploying surge protective devices that monitor and control disruptive, odd and deviant electrical activity adds an extra layer of protection. Likewise, implementing a consistent practice of transformer examination and testing to detect and mend early signs of wear and tear, or hints of weakness ensures that greater catastrophes are avoided.

Signs it’s time to upgrade your furnace’s electrical components

It is important to upgrade your furnace’s electrical components when you notice signs of inefficiency or looming failure. One of the signs could be short cycling or the furnace struggling to heat the building, it could be caused due to old wires or a defective control board. Buzzing and humming noises could indicate electrical breakdowns and loose connectors. If you experience a gradual increase in energy surges without any clear explanation, then your furnace’s electrical parts could potentially be dead. Other signs include irregular supply or interruptions of power or frequent sensors shutting down. By replacing such components you will not only increase safety but also improve efficiency and save some energy.

References

Frequently Asked Questions (FAQ)

Q: What is an HVAC transformer and how does it work in a furnace?

A: An HVAC transformer is a device that transfers electrical energy between two or more circuits through electromagnetic induction. In a furnace, it helps convert high voltage electricity to a lower voltage, typically 24 volts, which is necessary for the control systems of the furnace to operate safely and efficiently.

Q: How can I tell if I have a bad furnace transformer?

A: Signs of a bad furnace transformer include the furnace not turning on, unusual noises like humming or buzzing, or the circuit breaker tripping frequently. If your furnace isn’t operating as it should, it may be due to a faulty transformer.

Q: What role does a voltage transformer play in my HVAC system?

A: A voltage transformer in an HVAC system steps down the high voltage from the main power supply to a lower voltage required by the furnace’s control circuits. This ensures that all components receive the appropriate power level to function correctly.

Q: Can I use a 240v to 24v transformer for my Goodman furnace?

A: Yes, a 240v to 24v transformer can be used for a Goodman furnace, provided that it meets the system’s requirements, such as having the correct voltage regulation and being a transformer compatible with Goodman specifications.

Q: What is a 40va control transformer and why is it important?

A: A 40va control transformer is a type of step-down transformer that provides a 24-volt output with a power rating of 40 volt-amperes (VA). It is crucial in HVAC systems to supply the necessary power to control circuits and components like the thermostat and blower motor.

Q: What causes a furnace transformer to fail?

A: Common causes of furnace transformer failure include electrical surges, overheating, poor voltage regulation, or physical damage. Regular maintenance and ensuring compatibility with your furnace can help prevent transformer issues.

Q: How do I replace a bad transformer in my furnace?

A: To replace a bad transformer, first ensure that the power to the furnace is turned off. Remove the old transformer by disconnecting the wires and unscrewing it from its mount. Install the new transformer by securing it in place and reconnecting the wires. Make sure the new transformer meets the system’s requirements, such as being a 240v secondary 24v or primary 120 as needed.

Q: What is a transformer channel 2 hole mount?

A: A transformer channel 2 hole mount refers to the mounting design of a transformer, where it is secured in place using two holes. This design ensures stability and proper alignment within the HVAC system.

Q: Is a step-down transformer the same as a control transformer?

A: While both step-down transformers and control transformers reduce voltage levels, a control transformer is specifically designed to provide power for control circuits in devices like HVAC systems. It often has additional features for better voltage regulation and reliability.